IIAR 2 – 2021 Standard for Design of Safe Closed-Circuit Ammonia Refrigeration Systems has been released by the IIAR and is now available for purchase on their website.

The updated standard has several new requirements which resulted in some changes in the PSM/RMP program templates. Here are some of the highlights:

- The definitions file was updated with new IIAR 2 definitions. Added in-document headings to skip around the document easily.

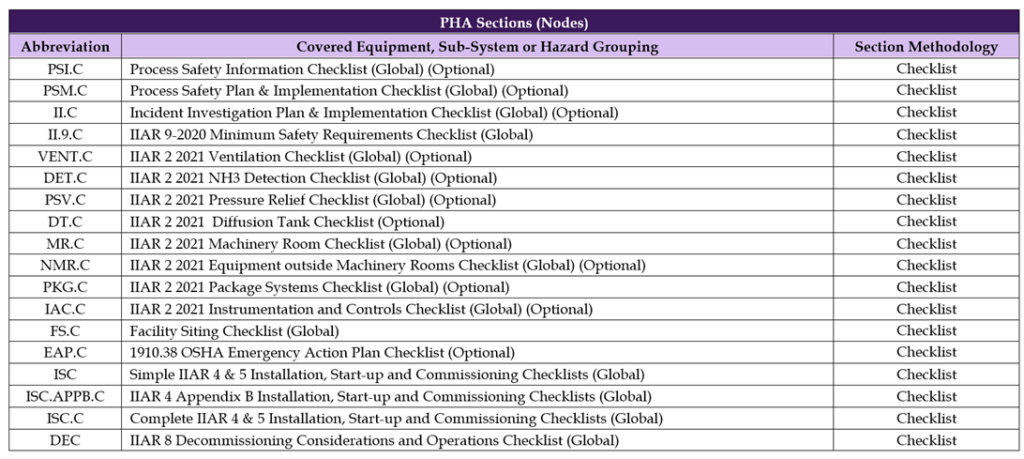

- The PHA Checklist Template was updated to the new IIAR 2:

- Added a note that “Provisions for plugs or caps required under IIAR 2 5.9.3.3” on all oil draining plug/cap questions.

- Added a note that “IIAR 2-2021 5.12.2 requires a check valve during charging” in relevant Charging SOP section.

- Added a question on Provisions for Pumpout per IIAR 2-2021 5.12.6 on PV1 subsection and all Equipment Subsections.

- Added/Modified questions on RC1 section about low ambient temperature, and VFD resonance.

- Added a question on EV2 (Liquid Heat Exchanger) equipment subsection regarding secondary coolant side pressure ratings.

- Added a question on MR.C Checklist for Classified Space signage.

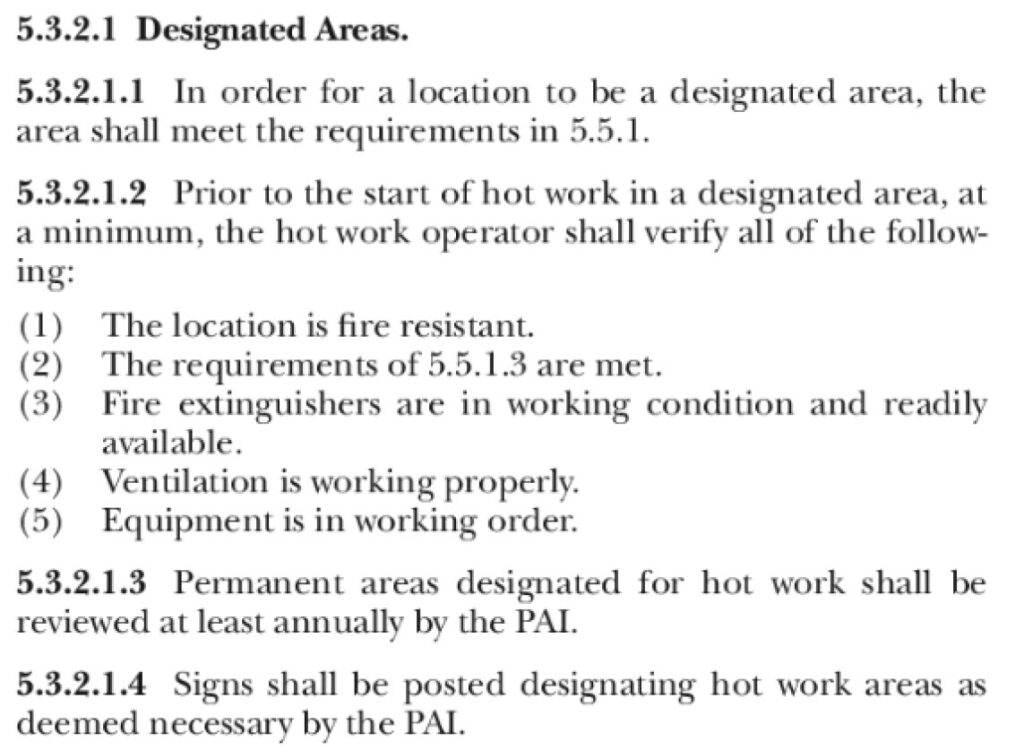

- Added a question on PV1 (Piping & Valves) on new MOPD & MSSPD requirements for valves leading to atmosphere.

- Added a question on PV1 (Piping & Valves) on requirements for unique identification for Emergency Shutoff valves.

- Modified existing .PSV equipment sub-subsections to include IIAR 2 2021 15.2.6 requirement that liquid relieving reliefs relieve back into the system.

- Added a note that IIAR 2 2021 13.2.3.1.1 limits carbon steel tubing and carbon steel compression fittings to valve sensing pilots, compressors, compressor packages, and packaged systems to all small-bore piping / tubing questions.

- Updated MR.C section for new requirements regarding NH3 detection.

- Updated various checklists (VENT, DET, PSV, DT) to match current IIAR 2-2021 text.

- Added a new equipment subsection NMR.C for IIAR 2 Equipment located outside of Machinery rooms.

- Added a new equipment subsection PKG.C for IIAR 2 Packaged Systems and Equipment.

- Added a new equipment subsection IAC.C for IIAR 2 Instrumentation Controls.

- Updated “Contractor Door Sign” to meet new IIAR 2 – 2021 [5.14.1.1] information standards and some ASHRAE 15 – 2019 [11.2.1] standards.

Comments about the changes and the required steps to implement the document changes are present in the “Change Log and Reference” document at 08/02/21.

…Read on further in this post if you want to know about the changes in the new IIAR 2…