What is IIAR 6?

ANSI/IIAR 6-2019 is the IIARs’ new Standard for Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems. To quote the forward from the public review:

This is a new standard intended to replace IIAR Bulletin No. 108 Guidelines for: Water Contamination in Ammonia Refrigeration Systems, IIAR Bulletin No. 109 Guidelines for: IIAR Minimum Safety Criteria for a Safe Ammonia Refrigeration System, IIAR Bulletin No. 110 Guidelines for: Start-Up, Inspection, and Maintenance of Ammonia Mechanical Refrigerating Systems, and IIAR Bulletin No. 116 Guidelines for: Avoiding Component Failure in Industrial Refrigeration Systems Caused by Abnormal Pressure or Shock. This new standard is intended to be a single source for the minimum requirements for ITM tasks for safe closed-circuit ammonia refrigeration systems.

Note: Design items pertaining to Bulletin No. 108 and Bulletin No. 116 are being considered to be incorporated in the next revision of IIAR 2, before these two bulletins are superseded.

When will it take effect?

Now that ANSI/IIAR 6-2019 has finished its Public Reviews, the end of this long journey is nearly over. Already approved by the IIAR Board of Directors and ANSI, the new standard should be published around July 1st.

Once the new standard is officially published it comes into effect once YOU or the AHJ adopt it. Most model codes are expected to adopt it in their 2021 review cycles.

Why should I care about it now?

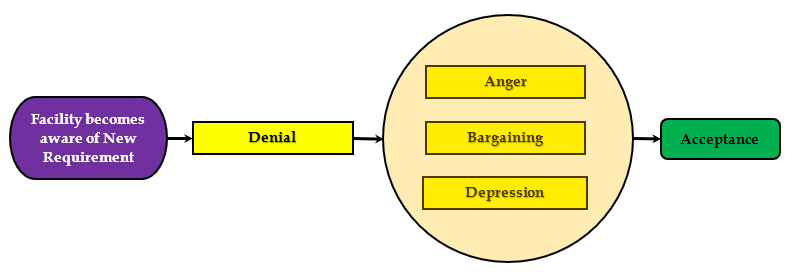

There are a few reasons:

- The old combination of outdated and scattered bulletins was difficult to follow and wasn’t updated to deal properly with modern equipment. ANSI/IIAR 6-2019 has a more modern sensibility.

- There’s really nothing in ANSI/IIAR 6-2019 you shouldn’t want to do – it’s all fairly sensible “good practice” advice.

- There’s a slightly lower administrative / MI overhead following the new standard than the old bulletins.

- I think – overall – that it’s easier to comply with ANSI/IIAR 6-2019 than the old combination of bulletins.

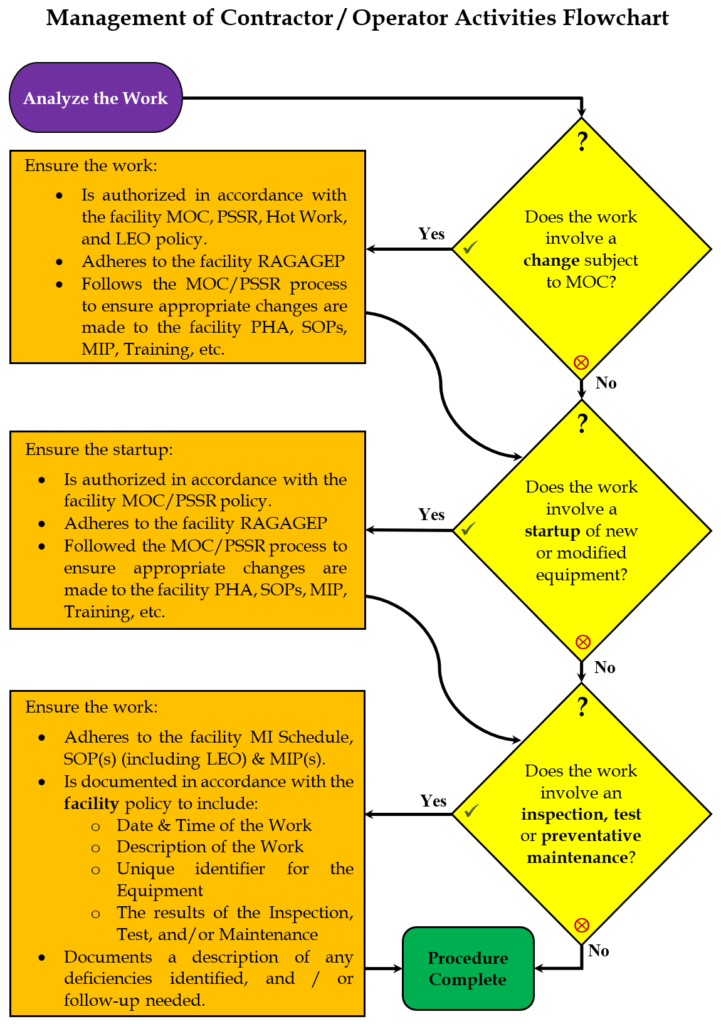

How would I go about ensuring compliance with IIAR 6?

You will have to thoroughly review ANSI/IIAR 6-2019 and perform a Gap Analysis between its requirements and your current PSM/RMP system. Pay special attention to:

- Your Mechanical Integrity element, schedule, work orders (ITPMRs) and MI procedures.

- Your SOPs to the extent that they deal with shutdowns, start-ups and turn-arounds.

What would such a Gap Analysis look like?

If you are using my template system, the good news is that I’ve updated the ENTIRE system to be ANSI/IIAR 6-2019 compliant. Because this has been a LARGE project that’s taken a lot of time, all the new files have been given the same date code: 030219.. You can grab the updated templates on the Google Shared Drive. Some things like the Element Written Plans, ITPMRs are plug-and-play, but others like the MI-EL1, SOPs, etc. will have to be customized for your facility. If (when) you update your PSM/RMP system, don’t forget to implement your MOC procedure! Please note: ALL future template additions will include the ANSI/IIAR 6 compliant text that has been added.

Below is my list of implementation challenges, observations, and changes

Challenge #1: Section 5.5.1.3 Inspection & Test documentation

While I applaud the IIAR for pointing out the necessary requirements for a FUNCTIONALLY EFFECTIVE MI system, it’s a very real possibility that this section and its requirements will be interpreted to require this documentation IN THE MI system. That’s unrealistic for some of the information and experience has shown us that it’s likely unworkable in the field. Below is a table that shows the IIAR documentation requirements and how they are handled in the PSM system.

|

IIAR Cite

|

Requirement |

How it’s Handled |

| 5.1.1.3.1 |

Date of the inspection or test. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.2 |

Name of the individual or individuals that performed the inspection or test. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.3 |

Serial number or other identifier of the equipment on which the inspection or test was performed. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.4 |

Description of the inspection or test performed. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.5 |

Recommended corrective action(s) for each deficiency identified. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.6 |

Description of corrective action(s) for each deficiency identified. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.7 |

Identification of each designated responsible person assigned and authorized to remedy each deficiency identified. |

OSHA/EPA requirement. Handled in the Management System master recommendation tracking form RT-1. NOT duplicating this information on MI docs. |

| 5.1.1.3.8 |

Results based on the conditions at commencement of the inspection or test, including instrumentation readings. |

This is already covered in the ITMPR Corrective Actions, Recommended Actions & Comments section if implemented correctly. |

| 5.1.1.3.9 |

Expected activation set points (+/-) including a functional description of the control logic. |

This information is already provided in the respective equipment RESOPs and system level ROSOPs. Since all our ITPMRs are used in conjunction with the SOPs this should be sufficient. |

| 5.1.1.3.10 |

Results based on the conditions after completion of the inspection or test, including instrumentation readings. |

OSHA/EPA requirement already handled on ITPMR. |

| 5.1.1.3.11 |

Expected completion date(s). |

OSHA/EPA requirement. Handled in the Management System master recommendation tracking form RT-1. This may be handled through a CMMS, but we’re NOT duplicating this information on our MI docs. |

| 5.1.1.3.12 |

Actual completion date(s). |

OSHA/EPA requirement. Handled in the Management System master recommendation tracking form RT-1. This may be handled through a CMMS, but we’re NOT duplicating this information on our MI docs. |

Challenge #2: Section 5.2, Table 5.2

The IIAR is introducing the same concept here as I did last year with the “Acceptable Task Frequency Window.” I think their window is over-broad and would not be comfortable defending it without further engineering rationale. For example, they are giving a 1 month window on a quarterly task vs. my 14 days, a 2 month window on a semi-annual task vs. my 1 month window. I’m sticking with my more conservative window for now, but – as always – you are welcome to change yours.

Challenge #3: Section 5.2

The IIAR is rightly calling out the need to re-evaluate task frequency based on a history of deficiencies. I’ve incorporated some of their wording directly in the MI Implementation Policy: Mechanical Integrity Schedule as follows: Where a history of repeated deficiencies has been recorded, task frequencies / methods should be re-evaluated. This is usually triggered through the Incident Investigation element and managed through the MOC/PSSR element.

The IIAR is also stating “Where a history of fault-free operation has been recorded, the (ITM) task frequencies are permitted to be decreased.” I am not comfortable with incorporating this wording into the written plan as while it is not necessarily wrong it is extremely difficult to defend without providing significant engineering rationale. OSHA has published a lot of guidance saying the opposite of what the IIAR is saying here, and while I believe OSHA is wrong in their guidance, we should probably pick-and-choose your battles better than this.

Challenge #4: Section 5.3.6

5.3.6.1 – This section implements a few new logs/documentation requirements, including the “Procedure for Communicating between shifts” that the CCPS has long recommended. Those using the COM-LOG (as outlined in the Employee Participation Written Plan) were already handling this well. To improve the system though, that section has been moved from the EP plan and placed in the RMP (Management System) Written Plan and renamed “Written Communication Log.”

5.3.6.2 requires documentation on secondary coolants. The ITPMR HX-90 & ITPMR HX-365 already does much of this but a new line adds “If any glycol was added / removed, record the type and amount.” While in this section, removed all the references to Glycol and replaced with Fluid so it can be used with Brine and Glycol systems.

5.3.6.3 requires documentation of the NH3 test records. The required information was added to a new ITPMR: ITPMR-NH3 and it was added to the MI-EL-1.

5.3.6.4 requires documentation of the addition / removal of any oil. Created a new log called OIL-LOG and updated all PU, PV & RC ITPMRS to include a reference to this log during oil addition/draining steps.

5.3.6.5 requires documentation of the lubrication type, quantity needed, and quantity used. Created a new log called the LUBE-LOG and updated all AU, HX, EC, RC & VENT ITPMRS to include a reference to this log during lubrication steps.

5.3.6.6 requires documentation of Relief Valves. I have no intention of creating a log for this as all the information should be in the PSI and whatever work order / ITPMR was used to replace the relief valve. To make this easier, I’ve included new text in the ITPMR-PRV-365 “If the relief valve is to be replaced, the new valve model number and pressure setting must be confirmed and recorded by TWO people before replacement to be considered a “Direct Replacement.” “In-Kind” and other types of replacements must be handled in accordance with the facility MOC policy.” I’ve also included signature boxes in that ITPMR line item.

Challenge #5: Section 5.3.7

This section deals with record retention requirements. The advice given here by the IIAR does not seem to reflect the RMP and PSM guidance given by the EPA and OSHA and has therefore been skipped. A careful reading of the informative appendix shows that the drafters of this document understood that MI documentation needs to be kept for the life of the process. In any case, we’re in a digital world so you can avoid the argument entirely if you scan the documents, put them on a cloud-based server, and recycle the paper.

Challenge #6: Section 5.4.2

This section replaces the old IIAR B110 5yr Independent Inspection. It includes qualifications & conflict-of-interest requirements. In the informative appendix, they’ve also buried a certification requirement. All these requirements have been added in the Mechanical Integrity Written Plan under the Implementation Policy: Five Year Independent MI Inspection. To make my customer’s lives easier, I’ve also included a Responsible Person certification page in my MI Report Template as well as a signed statement regarding conflict-of-interest signed by the Team Leader for my MI Inspections, PHA’s and Compliance Audits.

Challenge #7: Section 5.5.1

This section deals with calibration of the instruments used in tests and inspections. I have included similar requirements in the ROSOP-QA concerning gauges for a long time, but it’s often ignored. We need to re-emphasize this issue! The ROSOP QA Pressure Gauge section was renamed to Testing Instrument and reworded to cover the additional ANSI/IIAR 6-2019 requirements.

PSM Program / Template Changes: The entire template PSM/RMP program was altered to conform with ANSI/IIAR 6-2019. All changes made in the 030219 templates are outlined below:

ALL PSM / RMP Element Written Plan Changes

- Moved Definitions from individual element Written Plans References and Definitions Section to a stand-alone document. The stand-alone definitions document was placed in the RMP / Management System binder / folder. The total list of definitions was expanded to cover much of the same ground as IIAR 1 – Definitions. Where the definitions I use varied from the IIAR significantly, I added the IIAR definitions with a “Per IIAR, …” at the end of the definition I’m using. Where IIAR definitions are used, they were updated to the most recent version of IIAR 1. Added the new ANSI/IIAR 6-2019 definitions to the stand-alone definitions document.

RMP / Management System Element Written Plan Changes

- Moved Implementation Policy: Written Communication Log (COMLOG) from Employee Participation to this Plan. (Not specifically required by ANSI/IIAR 6-2019 but a good idea I’ve wanted to implement for a while)

- Moved the content of Implementation Policy: PSM Meeting Notes from Employee Participation to this Plan. Also expanded this section to include some suggested agenda items for PSM Team Meetings. (Not specifically required by ANSI/IIAR 6-2019 but a good idea I’ve wanted to implement for a while)

EP PSM / RMP Element Written Plan Changes

- Renamed Implementation Policy: Communication between Shifts (COMLOG) to Implementation Policy: Written Communication Log (COMLOG) and moved it to the RMP (Management System) Written Plan. (Not specifically required by ANSI/IIAR 6-2019 but a good idea I’ve wanted to implement for a while)

- Moved content of Implementation Policy: PSM Meeting Notes to Implementation Policy: PSM Team Composition, Meeting Documentation and Agenda in the RMP (Management System) Written Plan. (Not specifically required by ANSI/IIAR 6-2019 but a good idea I’ve wanted to implement for a while)

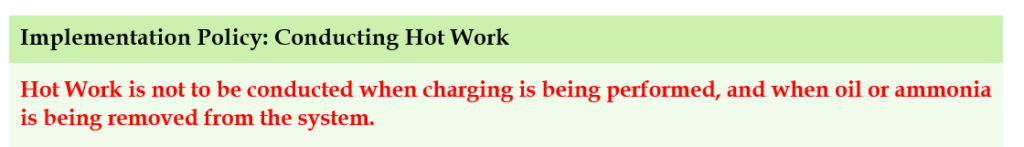

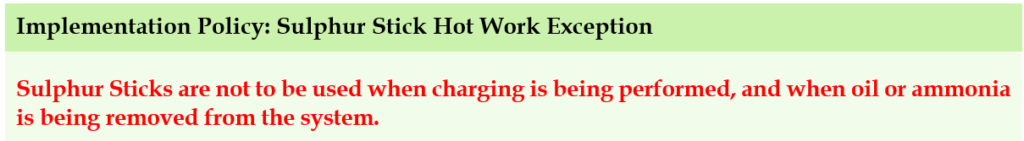

HW PSM / RMP Element Written Plan Changes

- Updated both versions of the template to include explicit statement on NOT performing Hot Work or using Sulphur Sticks during Charging, or when removing Oil / NH3 from the system. (IIAR 6 5.6.3.4)

PSSR PSM / RMP Element Plan Changes

- Updated ALL the PSSR forms (Word) to match the new 1yr ITPMRs. Maybe someday I’ll create the PDF forms again but it’s a lot of work and I’d rather we all work with the new ITPMRs to validate / field verify them before I expend that effort.

- Added new ITR-LP-PSSR for non-ammonia Liquid Pumps

MI PSM / RMP Element Written Plan Changes

References and Definitions

- Added ANSI/IIAR 6-2019 as a standard reference

- Added IRC MI Guidebook as a standard reference

Implementation Policy: Mechanical Integrity Schedule

- Slight change to first sentence to clarify that this policy is covering the Ammonia Refrigeration System to cover the same ground as IIAR 6 5.1.1

- Added language concerning modifying the schedule based on a history of recorded deficiencies.

- Added IIAR 6 5.2.3 language concerning daily tasks not being required during holidays/weekends.

Implementation Policy: Mechanical Integrity Task Documentation

- Modified the Corrective Actions, Recommended Actions & Comments section to improve the explanation of what’s expected in the ITPMR forms to cover the same ground as IIAR 6 5.1.1.3.8

Implementation Policy: Access to MIPs and Manufacturer’s Equipment Manuals

- Modified this section for clarity so that it clearly includes all Process Operators and refrigeration Contractors. Removed specific location wording. (IIAR 6 5.3.2)

MI-EL-1 Maintenance Schedule / Checklist Changes

- Added a line for Generators / Standby power sources (IIAR 6 5.5.4)

- Added a line for Ammonia Hoses (IIAR 6 11.1.4, 11.1.5)

- Changed IIAR B110 references to ANSI/IIAR 6-2019

- Added Filename / Template Revision to the bottom of the Checklist. (Not specifically required by ANSI/IIAR 6-2019 but a good idea I’ve wanted to implement for a while)

ITMPR Changes

ALL ITPMRS

- Added color banding. Thanks Scott!

- Re-organized tasks for more grouping.

- Set ITPMT tables to repeat Header Row as several ITPMRs are now two pages

- Standardized (hopefully) the formatting of the numbered / bulleted lists

- Re-organized the catch-all sections at the end. These are now a little bit longer, but they seem to be easier to read / follow now. Thanks to Scott for the idea.

- Incorporated some additional items from field feedback. Thanks Jeremiah, Scott & Victor!

- Added new ITPMR-LP for non-ammonia Liquid Pumps

Note: none of the above are specifically required by ANSI/IIAR 6-2019 but I’ve wanted to implement them for a while.

ITMPR AHT-365, AHNT-365 (Ammonia Hoses)

- New ITPMRs based on ANSI/IIAR 6-2019 Table 11.1.4 & 11.1.5 to cover Ammonia Hoses (Transfer and Non-Transfer)

ITMPR AC-30, AC-365 (Air Curtains)

- Added Lube-LOG reference

- Incorporated IIAR 6 Table 11.1.6 valve items into the annual ITPMRs

ITMPR AP-365 (Ammonia Pumps)

- Added Lube-LOG reference

- Incorporated IIAR 6 Table 7.1 items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

ITMPR AU-90, AU-365 (Air Units)

- Added Lube-LOG reference

- Incorporated IIAR 6 Table 9.1 items into the ITPMR

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMR

ITMPR DETECT-180 (NH3 Detectors)

- Incorporated IIAR 6 Table 12.3 items into the ITPMR

ITMPR DT-90, DT-365 (Diffusion Tanks)

- Reformatting / Renumbering for consistency with other ITPMRs.

- Added leak / freeze protection checks

ITMPR EC-30, EC-90, EC-365, EC-SD (Evaporative Condensers)

- Added Lube-LOG reference (EC-90, EC-365, EC-SD)

- Renumbered EC-90 to EC-180 (MI-El-1, Checklist)

- Incorporated IIAR 6 Table 8.1 items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

ITMPR HX-90, HX-365 (Heat Exchangers)

- A new item “If any glycol was added / removed, record the type and amount.”

- Added Lube-LOG reference

- Replaced references to Glycol with Fluid so it can be used for Brine systems as well.

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

ITMPR MI-5yr (5yr MI)

- Incorporated new ANSI/IIAR 6-2019 requirements in the ITPMR

ITMPR MR-365 (Machine Room)

- Incorporated ANSI/IIAR 6-2019 Table 12.2 items into the ITPMR

ITMPR NH3 (Ammonia)

- New ITPMR based on IIAR 6 Table 15.1

ITMPR PIPE-365

- Incorporated IIAR 6 Table 11.1 items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

ITMPR PRV-365 (Pressure Relief Valves)

- Included new text in the ITPMR-PRV-365 “If the relief valve is to be replaced, the new valve model number and pressure setting must be confirmed and recorded by TWO people before replacement to be considered a “Direct Replacement.” “In-Kind” and other types of replacements must be handled in accordance with the facility MOC policy.” (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Included verification signature boxes in the valve replacement ITPMR line item. (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMR

- Incorporated IIAR 6 Table 13.1 items into the ITPMR

ITMPR PU-90, PU-365 (Purgers)

- Combined Hansen and Parker into single ITPMR (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Added Oil Drain line and OIL-LOG reference

- Incorporated IIAR 6 Table 14.1 items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

ITMPR PV-90, PV-365 (Pressure Vessels)

- Added OIL-LOG reference

- Added note to “operating within limits” question on PV-365 to remind the user to check pressure and temperature

- Incorporated IIAR 6 Table 10.1 daily items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMRs

RC-30, RC-90, RC-365 (Refrigeration Compressors)

- ITMPR Removed RC-30 (MI-El-1, Checklist)

- Added check that setpoints are appropriate for connected vessels (RC-90, RC-365)

- Added Lube-LOG reference (RC-90, RC-365)

- Added OIL-LOG reference (RC-90, RC-365)

- Incorporated IIAR 6 Table 6.1 items into the ITPMRs

- Incorporated IIAR 6 Table 11.1.6 valve items into the ITPMR

ITMPR SS-7, SS-365 (Safety Showers)

- Incorporated IIAR 6 Table 12.5 items into the ITPMRs

ITMPR VENT90, VENT365 (Machine Room Ventilation)

- Added additional IIAR 2 checks to VENT-365

- Incorporated IIAR 6 Table 12.1 items into the ITPMRs

SOP (RESOP & ROSOP) Template Changes

All

- While leak-checking was already addressed to some degree, there was some room for improvement. A leak check reminder has been placed in the LEO Return to Service A leak check task has been placed in ALL equipment SOP steps that open Isolation Valves in the Normal Startup procedural section (IIAR 6 5.5.3)

- Where it wasn’t already done, all Normal Startup steps re-arranged to ensure that we are opening the unit to the system starting with he lowest threat and working towards the greatest threat: suction -> DC -> hgd -> liquid (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- For ALL Equipment RESOPS:

- Slightly reworded Emergency Shutdown section to make it simpler. (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Removed any specific MI steps from the Maintenance sections. We’re simply kicking it to the MI-El1, equipment-specific ITPMR’s and IOM’s. (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

ROSOP LEO – Line & Equipment Opening

- Added leak check reminder in Return to Service section.

ROSOP SWT – System Walkthrough

- Incorporated all ANSI/IIAR 6-2019 tables daily / weekly items into the ROSOP

- Changed “Engine Room” to “Machine Room” everywhere I could find it! (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Harmonized text between the RESOP “Monitor Normal Operations” sections and this document. (Not specifically required by IIAR 6 but a good idea I’ve wanted to implement for a while)

- Added Autopurgers to Machine Room section

ROSOP QA – Quality Assurance

- Added a section on Ice Accumulation (IIAR 6 5.6.8)

- Updated Vessel & Pipe sections to include new guidance on corrosion. (IIAR 6 10.1.1-2)

- Updated Pipe section to include new guidance on allowable thickness, Table A.11.1.1.3.1 Piping Sizes, Schedules, and Thicknesses (IIAR 6 A.11.1.1.3.1)

- Updated Vessel section to include new guidance on nameplates. (IIAR 6 10.1.4)

- Renamed Pressure Gauge section to Testing Instrument and provided additional ANSI/IIAR 6-2019 requirements. (IIAR 6 5.5)

RESOP AP – Autopurger

- Incorporated Table 14.1 (autopurgers) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

RESOP AU – Air Unit

- Incorporated Table 9.1 (evaporators) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

RESOP C – Compressors

- Incorporated Table 6.1 (compressors) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

RESOP EC – Condensers

- Incorporated Table 8.1 (condensers) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

RESOP HPRTSR – Non-recirculating Vessels

- Incorporated Table 10.1 (vessels) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

RESOP HTR – Recirculating Vessels

- Incorporated Table 7.1 (pumps) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.

- Incorporated Table 10.1 (vessels) daily items into the Monitor Normal Operations Section.

RESOP HX – Heat Exchangers

- Incorporated Table 9.1 (evaporators) daily items into the Monitor Normal Operations Section and harmonized that section with the ROSOP SWT Walkthrough procedure.