Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

Chill - We Got This!

Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

(Apologies for the late post – a scheduled post did not happen. These changes took place 3/8/24)

The Various ITPMR’s, the Walkthrough Form & SOP, etc. were all re-reviewed line-by-line to ensure closer compliance with IIAR 6. Many, many changes were made based on this review. A detailed changelog follows:

IIAR 9-2020 Addendum A (202x) First (1st) Public Review

Public Review Announcement

IIAR invites you to make comments for IIAR’s first (1st) public review of IIAR 9-2020 Addendum A (202x) Safety Standard for Minimum System Safety Requirements for Existing Closed-Circuit Ammonia Refrigeration Systems.

Public Review Period: October 27th, 2023 through November 26th, 2023

Comments must be submitted to the IIAR Headquarters by 5:00 pm EST on November 26th, 2023. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

You can review the document and make your voice heard at this link.

CFATS Announcement

As of July 28, 2023, Congress has allowed the statutory authority for the Chemical Facility Anti-Terrorism Standards (CFATS) program (6 CFR Part 27) to expire.

Therefore, CISA cannot enforce compliance with the CFATS regulations at this time. This means that CISA will not require facilities to report their chemicals of interest or submit any information in CSAT, perform inspections, or provide CFATS compliance assistance, amongst other activities. CISA can no longer require facilities to implement their CFATS Site Security Plan or CFATS Alternative Security Program.

CISA encourages facilities to maintain security measures. CISA’s voluntary ChemLock resources are available on the ChemLock webpages.

The EPA has made a relatively small update to the process of submitting, updating, or correcting your RMP filing. The change is minor, but if not accounted for, it can slow down or stop your filing process.

What Changed?

It has always been a requirement for the Certifier (and Preparers) to have profiles established through the CDX portal, but the identity proofing and CDX Electronic Signature Agreement (ESA) components are new.

It’s possible that this identity proofing and signature agreement are already taken care of, but it would still be prudent to ensure your Certifier has met these requirements several weeks before your RMP submittal/update are due.

Who is Affected?

The Certifying Official for your process’s RMP filing is the only one affected. The EPA defines these people as:

“Certifiers are facility owners or operators who must certify the accuracy and completeness of the information reported in the RMP. They have signed and submitted a one-time Electronic Signature Agreement (ESA) to the EPA. The ESA legally binds the Certifier’s electronic submission to their signature. Only Certifiers can submit the RMP.”

This is usually a plant manager, owner, or some other member of upper management. In order to be respectful of their time, it would be good to let them work through these new requirements well before the filing is due.

If you believe that your Certifier has already met these requirements, here is what the EPA’s guidance suggests to verify:

”Some existing users may not be impacted if they previously completed identity proofing and signed a standard CDX ESA for another program service that uses the same CDX organization as their RMP*eSubmit Certifying Official role.

…

Existing Users who Registered Before February 24, 2023

Existing users who have not verified their identity or without a standard CDX ESA will be prompted to complete identity verification and ESA when they access the RMP*eSubmit for the first time. The one-time process can be initiated by logging into CDX and clicking on the “Certify Submission” role link. Users will be able to complete this process using one of the below methods:

Once the above electronic or paper process is complete, you will be able to access RMP*eSubmit.”

The EPA’s RMP eSubmit User Manual has more information, and detailed step-by-step instructions for any CDX portal or RMP filing questions you may have. (Link functional as of June, 2023)

As always, we will continue to track any changes we can find concerning Ammonia Refrigeration process safety. Any changes or updates will be posted here and accounted for in the OSPSM compliance templates. If you have questions or would like to find out more, please contact the RC&E Safety and Compliance team (safety@rce-nh3.com).

“Time Waits for No one…”

The Issue at hand

When I first started in NH3 refrigeration, you could pick up the phone, talk to your parts-guy, and get a replacement valve quickly: often the same day, but usually within a business day or two. While you were waiting for the part, you either operated the equipment manually (requiring a temporary SOP / MOC) or shut the equipment down during the wait. We call the time between when you order something and when it arrives, lead-time.

Because lead-times *were* short, parts inventory at most facilities were kept fairly low – usually limited to what would stop production. If you could get what you needed in a day or two, why keep it on the shelf, unless you were losing 20k+ an hour in downtime?

The situation has changed around us, and I’m not sure we’ve all thought through the implications of the current supply-chain issues. Lead-times have grown substantially in 2021 and, while relief is promised in the second half of 2022, these long wait times for equipment and components have the potential to adversely affect our Process Safety.

Current Lead Time estimates

| Equipment / Component | Lead-Times in Weeks* |

| Valves, Shutoff and Control | 14-24 |

| Valves, Relief | 12-20 |

| Vessels | 14-24 |

| Condensers | 14-16 |

| Compressors | 16 |

| Air Unit / Evaporators | 36 |

| Heat Exchangers | 14 |

*Typical for NH3 components. Varies by brand. Some halocarbons lead-times are even longer.

How can this affect Process Safety?

When you don’t have a critical spare part, and won’t have one for several months, production demands are likely to force you to operate your equipment in “temporary” modes. Here are a few thoughts:

What should I do?

“The first responsibility of a leader is to define reality…” –Max DePree

Well, the first step is to start a discussion with your skilled technicians and make sure they understand the environment we’re all working in. Here are some points for discussion, and further actions to take:

RC&E can assist you with your parts and spares. Click Here for our Line Card. Call Dennis Vaught 817-210-1957 or email him at dvaught@rce-nh3.com

One of the most frequent misconceptions we’ve been dealing with in our industry is a belief that being below the PSM/RMP threshold means you are in some sort of wild-west no-man’s-land where there are no rules. Previously we’ve dealt with that issue in a post called “General Duty vs. PSM/RMP: Is there a benefit to dropping below the 10,000lb threshold?” But that post was really written to people that were considering lowering their NH3 inventory to avoid regulation.

We thought it would be useful to put together an article that dealt with those systems that were already under the PSM/RMP threshold so they better understood the Safety & Regulatory landscape. To that end, we’ve put the information in a executive level 3-page pdf that is easy to email: Ammonia Process Safety below 10k

Email or call us today to have RC&E assist you with all your PSM/RM Program needs! info@RCE-Chill.com (888) 357-COOL (2665)

IIAR 2 – 2021 Standard for Design of Safe Closed-Circuit Ammonia Refrigeration Systems has been released by the IIAR and is now available for purchase on their website.

The updated standard has several new requirements which resulted in some changes in the PSM/RMP program templates. Here are some of the highlights:

Comments about the changes and the required steps to implement the document changes are present in the “Change Log and Reference” document at 08/02/21.

…Read on further in this post if you want to know about the changes in the new IIAR 2…

The issue: A facility with an ammonia refrigeration system notes that their HPR level is rather low, and they are considering ordering some ammonia to get back to the levels they “used to have.” The thinking is that they need to add to the ammonia charge to make up for ammonia that was lost over the years.

Before you go too far, a good question to ask is: Did I lose ammonia? Or is it just somewhere else in my system?

What if you didn’t lose it?

Did you add equipment without your MOC addressing if this required an inventory adjustment? Did you change recirculator vessel levels which make the HPR look low even though the ammonia is still out in the system? Has someone been mucking with the HXV’s or TXV’s, so you are “brining” coils? These are common issues, but the most likely culprit is seasonal variation.

If it’s August in Texas, it’s likely that your system is running about as hard as it will ever run. That means that the NH3 isn’t just hanging out in your vessels, but out in the various heat exchangers (and their piping) doing its job. The “good old boy” method of testing this was to wait until the cool of the night, shut down the liquid feed to your “load,” and check the vessel levels after the NH3 came back.

A more “modern” method is to use an inventory spreadsheet and adjust the levels in the heat exchangers to reflect the summer load. The intricacies of doing either of these are better dealt with in the real world rather than a blog-post, so let’s assume you have already checked this and you actually do need ammonia. (Note: if you need assistance with either of the above, we can certainly assist you, just give us a call)

Ok, maybe we did lose it!

If you look into the situation and find out that you actually do need ammonia, there are a few considerations you should think of BEFORE you order that truck and start preparing for delivery.

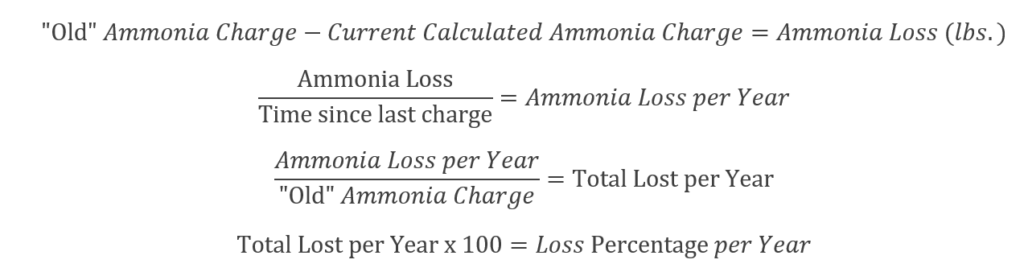

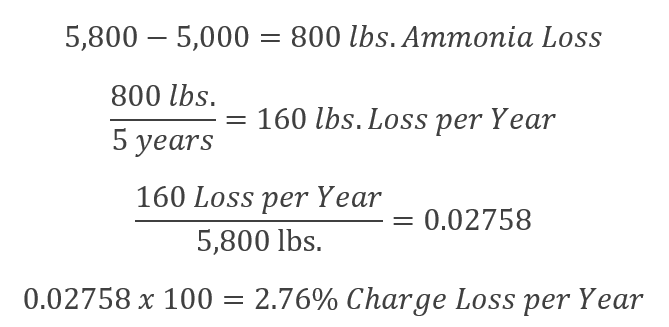

Justifying the charge

Assuming you didn’t have some sort of incident that clearly explains why you need ammonia, we should figure out how to justify the amount we’re adding. Most losses are easily justified by establishing a “loss rate” and comparing it to accepted norms. This acceptable loss would be caused by normal maintenance, auto-purgers, and fugitive emissions.

In my opinion, anything less than 5% is good. 2-3% is excellent. For what it’s worth, the IIAR has stated that up to 10% loss a year is “reasonable.”

A loss rate of 3% or less a year can easily be explained from normal maintenance, auto-purgers, and fugitive emissions.

This is easier to explain with a worked example from a friend. In this case, their inventory level is supposed to be 5,800lbs. When they updated their inventory sheet to reflect the actual conditions at the facility, they saw a calculated current charge of 5,000lbs reflecting an 800 pound loss. That loss occurred since their last charge 5 years ago.

This percentage is easily explainable from maintenance and other fugitive emissions, and it’s also quite reasonable.

If you take the time to figure out the math above, and then document your calculations to justify your NH3 charge, it helps avoid unpleasant assumptions on the part of the EPA and OSHA in any future inspections.

If an auditor comes in and sees an ammonia delivery receipt, a documented rationale why the ammonia was needed, the SDS of the chemical charged, and you have a compliant charging procedure, it would be very unlikely that the charging process would be questioned further.

Of course, if your math shows a high leak rate, then you had better get an incident investigation going and figure out what’s wrong!

P.S. – To assist in this effort, Scott updated the Ammonia Inventory example template has been updated to help automate this process. Just enter the old value, newly measured value, and time (in months) since last charging and you have a 1-page report on the % loss per year. We hope this helps. The file can be located at: \ PSM-RMP Program Templates \ 03 – Process Safety Information \ Optional Resources \

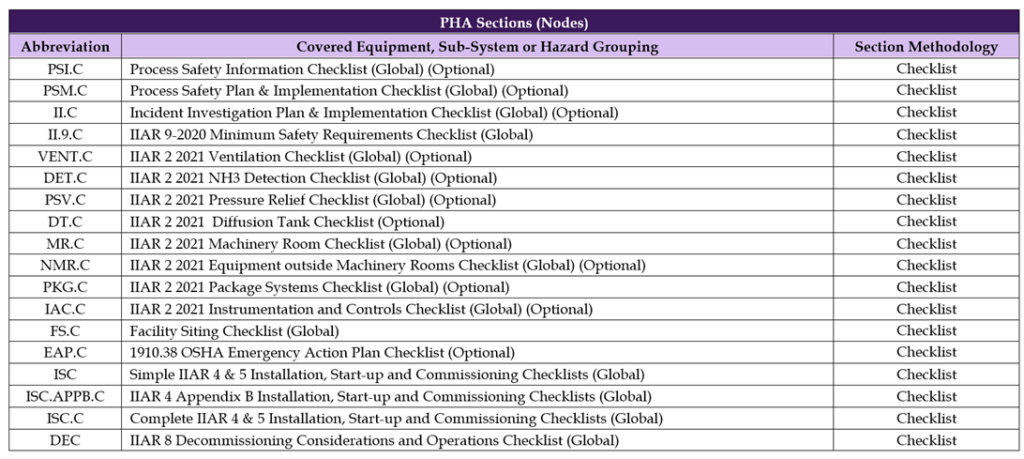

According to 1910.119(e) and 40CFR68.67(a) the purpose of a PHA is to “…identify, evaluate, and control the hazards involved in the process.” Since the mid-90’s the refrigeration industry has done this mainly through the IIAR’s “What-If” methodology as suggested in their Compliance Guidelines materials.

There have been many revisions of this material over the years, but they all have the same thing in common as you use them: You can see how each question / item:

For example, a question might ask something like “What if plugs, caps, or blind flanges are missing on purge or drain valves?” This should prod you to recall that both IIAR 2 and IIAR 4 require that these things be plugged, capped, etc. This should also prod you to ask how you are addressing this requirement in your Process Safety Program.

The issue we always came across is that you must KNOW or MEMORIZE what the RAGAGEP says in a very complete way, or you miss the connection between the “What If” scenario and the RAGAGEP. This is nearly impossible because it seems like RAGAGEP is multiplying at an alarming rate. Furthermore, this (at least two day) process often feels like a futile effort at figuring out what the “What-If” scenario questions are really getting at.

To improve this years ago, I started adding two things to the IIAR standard questions:

It’s very easy to lose sight of evolving RAGAGEP over time. These checklists allow you to perform a forensic examination of your system compared to current RAGAGEP. In addition to the issue of improving RAGAGEP compliance, we also face other challenges.

This again leads us back to checklists. I created them for basic PSI & PSM items, Incident Investigations, IIAR 9, Facility Siting, EAP, IIAR 4, IIAR 6, and IIAR 8. Here’s what that looks like:

As you can see, that’s fairly comprehensive, but it’s also a lot more work! To adjust to all this, we usually perform PHA’s in a two-step process.

Step 1: Weeks in advance, we give the client the relevant checklists and have them fill them out to the best of their ability.

Step 2*: Once we’re on-site, we go over the checklists they’ve worked on to answer any questions, address discrepancies, etc. THEN we move on to the “What If” scenarios.

* Of course, if the client wants, we can always book another two or three days of our time helping them on-site with Step 1.

The result of this longer, more comprehensive process is:

You can learn more about our PHA offerings here. Email or call us today to have RC&E assist you with all your PSM/RM Program needs! info@RCE-Chill.com (888) 357-COOL (2665)