Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

Chill - We Got This!

Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

(Apologies for the late post – a scheduled post did not happen. These changes took place 3/8/24)

The Various ITPMR’s, the Walkthrough Form & SOP, etc. were all re-reviewed line-by-line to ensure closer compliance with IIAR 6. Many, many changes were made based on this review. A detailed changelog follows:

IIAR 2 – 2021 Standard for Design of Safe Closed-Circuit Ammonia Refrigeration Systems has been released by the IIAR and is now available for purchase on their website.

The updated standard has several new requirements which resulted in some changes in the PSM/RMP program templates. Here are some of the highlights:

Comments about the changes and the required steps to implement the document changes are present in the “Change Log and Reference” document at 08/02/21.

…Read on further in this post if you want to know about the changes in the new IIAR 2…

According to 1910.119(e) and 40CFR68.67(a) the purpose of a PHA is to “…identify, evaluate, and control the hazards involved in the process.” Since the mid-90’s the refrigeration industry has done this mainly through the IIAR’s “What-If” methodology as suggested in their Compliance Guidelines materials.

There have been many revisions of this material over the years, but they all have the same thing in common as you use them: You can see how each question / item:

For example, a question might ask something like “What if plugs, caps, or blind flanges are missing on purge or drain valves?” This should prod you to recall that both IIAR 2 and IIAR 4 require that these things be plugged, capped, etc. This should also prod you to ask how you are addressing this requirement in your Process Safety Program.

The issue we always came across is that you must KNOW or MEMORIZE what the RAGAGEP says in a very complete way, or you miss the connection between the “What If” scenario and the RAGAGEP. This is nearly impossible because it seems like RAGAGEP is multiplying at an alarming rate. Furthermore, this (at least two day) process often feels like a futile effort at figuring out what the “What-If” scenario questions are really getting at.

To improve this years ago, I started adding two things to the IIAR standard questions:

It’s very easy to lose sight of evolving RAGAGEP over time. These checklists allow you to perform a forensic examination of your system compared to current RAGAGEP. In addition to the issue of improving RAGAGEP compliance, we also face other challenges.

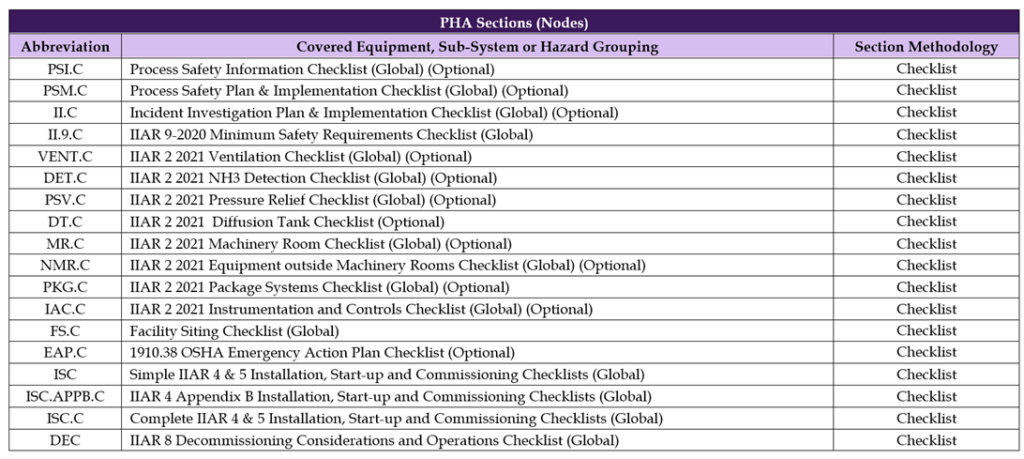

This again leads us back to checklists. I created them for basic PSI & PSM items, Incident Investigations, IIAR 9, Facility Siting, EAP, IIAR 4, IIAR 6, and IIAR 8. Here’s what that looks like:

As you can see, that’s fairly comprehensive, but it’s also a lot more work! To adjust to all this, we usually perform PHA’s in a two-step process.

Step 1: Weeks in advance, we give the client the relevant checklists and have them fill them out to the best of their ability.

Step 2*: Once we’re on-site, we go over the checklists they’ve worked on to answer any questions, address discrepancies, etc. THEN we move on to the “What If” scenarios.

* Of course, if the client wants, we can always book another two or three days of our time helping them on-site with Step 1.

The result of this longer, more comprehensive process is:

You can learn more about our PHA offerings here. Email or call us today to have RC&E assist you with all your PSM/RM Program needs! info@RCE-Chill.com (888) 357-COOL (2665)

Merry Christmas to our Ammonia Refrigeration Process Safety community!

Well, this year has been interesting, eh? The hits keep coming it seems, and it was no different to those of us in the Process Safety field. Behind the scenes, we’ve been working on a fairly major set of improvements to the PSM system. Originally scheduled for August, we’ve finally managed to push it across the finish line just in time for the Holidays!

Significant improvements were made to the core of the system (The SOPs and ITPMRs) through an unprecedented amount of end-user feedback. Remember, this system relies on the feedback of operators, technicians, service personnel, and Process Safety professionals to improve.

All updated documents have the 122520 date-code, but here’s a run-down:

To implement:

IIAR 4-2020 Installation of Closed-Circuit Ammonia Refrigeration Systems and IIAR 8-2020 Decommissioning of Closed-Circuit Ammonia Refrigeration Systems have been released by the IIAR and are now available for purchase on their website. IIAR 8 didn’t change much, but this was a very significant change to the existing IIAR 4 standard.

In SHORT, here’s what you need to know as an end-user:

The long version follows…

Continue reading

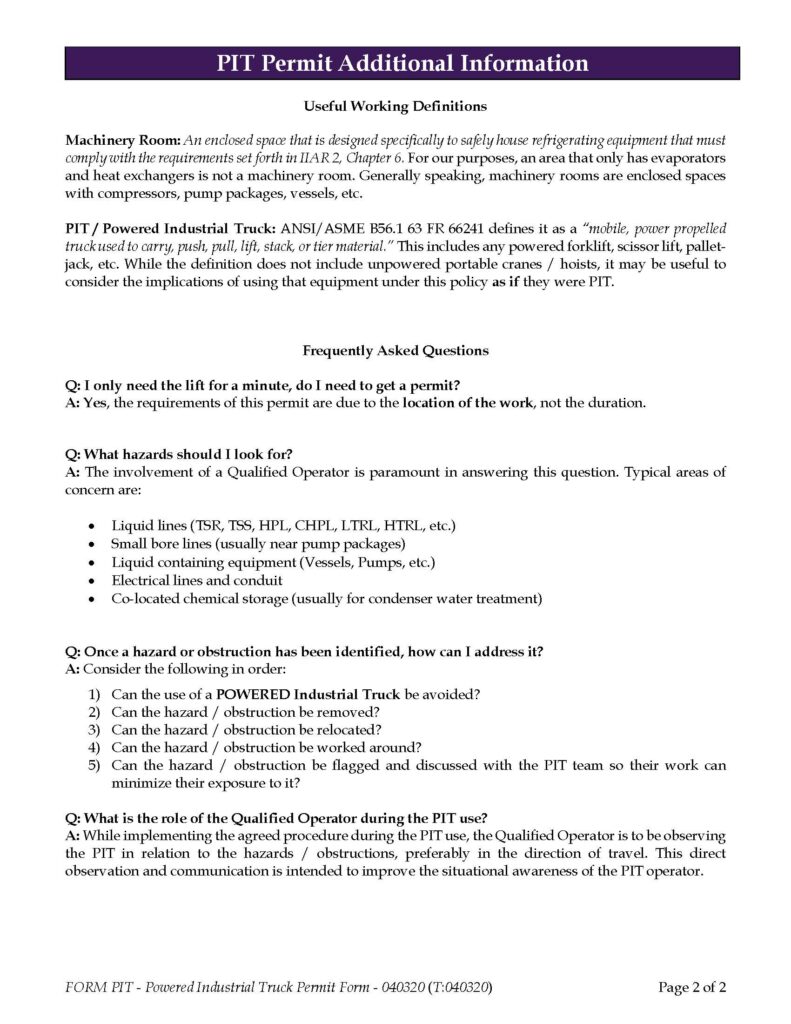

Powered Industrial Trucks (PIT) in Machine Rooms are a known struck-by hazard. What most people don’t realize is how serious the results of a PIT impact in a Machinery Room can be.

For example, a forklift / scissor lift impact that shears a 3″ TSS (ThermoSyphon Supply) or HPL (High Pressure Liquid) operating at a typical head pressure of 160PSIG results in a release rate of over 18,500 pounds per minute.

Many facilities attempt to establish a ban on PIT in their machinery rooms, but while the needs for PIT in machine rooms are very limited, there are situations where they are necessary. An outright ban won’t likely survive prolonged contact with reality.

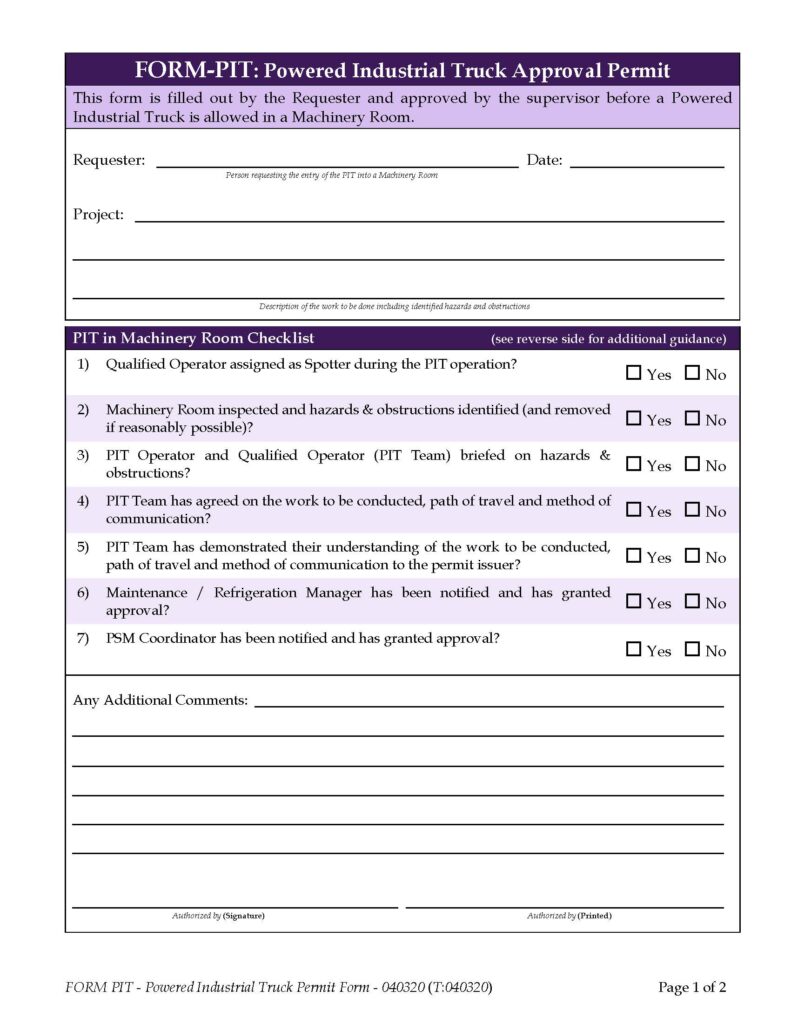

To address this issue in a PHA, we usually recommend a Written Machine Room PIT policy as an administrative control. For years we’ve discussed the content of that policy informally with people. Recently a PSM coordinator shared her written policy & permit with us and after some alterations and formatting, we’re adding it to the SOP Templates section.

Front of the Permit:

Back of the Permit with additional explanations:

As always, you can find this on the Google Shared template drive.

The story so far…

Dec 2016: Outgoing Obama EPA releases changes to the RMP rule on the way out the door.

Apr 2017: Incoming Trump EPA puts the RMP rule changes on hold.

Jun 2017: Trump EPA further delays the RMP rule changes.

May 2018: Trump EPA proposes new RMP rule changes, reversing Obama changes.

Aug 2018: DC District Court reverses Trump Rule and re-instates Obama rule essentially making it the existing rule with compliance dates in the past. Trump EPA is basically told that it can change the rules, but it needs to follow different procedures to do that. Trump admin appeals and the rule changes are put on hold.

Sep 2018: Trump admin loses appeals. Obama RMP rule changes are officially LIVE. Trump EPA announces that they will follow the different procedures and change the rule the right way. (Not-so-secretly, the entire EPA is told NOT to enforce the new rule, but out of an abundance of caution, most RMP adherents implement the changes anyway. After all, it IS the law.)

Dec 2019: Trump EPA officially posts the new rule and places it in the CFR making it LIVE on 12/19/19. (See links at the end of the post)

So, where do we stand now?

Ok, we’ve got a new RMP rule. It appears to have gone through the correct rulemaking process. It’s been published in the Federal Register making it the law of the land.

So, what do we do now?

Well, let’s be honest; the Trump administration IS GOING TO GET SUED over this. What happens then? Who knows!? If you follow the courts in modern America, you know there is very little that can be accurately forecasted.

What we do know is that we have a new rule. The new rule appears to have been done correctly with sound documentation as to the reasoning for the changes. In my opinion, the new rule will LIKELY hold up in court. Even if it doesn’t, it is highly unlikely the EPA could get away with fining / citing people for not following a court-reinstated rule under such a cloud of confusion.

In any case, the new rule is easier to follow and makes more sense than the Obama EPA rule changes did. It reverts the majority of the RMP rule to match the PSM rule where they SHARE jurisdiction. The only substantive changes are to the EPA-specific areas where the EPA alone holds jurisdiction.

Ok, so how do I comply with this new rule?

If you do use our template system, I’ve got some good news for you! This is where using a set of open-sourced, professionally curated templates really shines. ALMOST ALL THE WORK has been done FOR YOU!

Note: Estimated time for the above is about 2-4 hours depend on how well you know your PSM/RMP program.

On the other hand, If you don’t use our template system, you’re going to have to re-create the work I’ve already done:

Note: Estimated time for the above is about 40-80 hours depend on how well you know your PSM/RMP program and the EPA RMP rule.

Template Program changes in detail

Please note, where not specifically shown below all affected Element Written Plans had their CFR section updated to the current 12/19/19 CFR.

| Element | What Changed | Changes to Program Templates |

| 01 – RMP |

|

|

| 02 – EP | N/A | None |

| 03 – PSI |

|

|

| 04 – PHA |

|

|

| 05 – SOP | N/A | None |

| 06 – OT |

|

|

| 07 – CQ | N/A | None |

| 08 – MI | No changes to RMP requirements |

|

| 09 – HW | N/A | None |

| 10 – MOC / PSSR | No changes to RMP requirements |

|

| 11 – II |

|

|

| 12 – EPR |

|

|

| 13 – CA |

|

|

| 14 – TS |

|

|

Item-by-Item changes:

EPA links for new information:

The spirit of Christmas may be behind us, but the spirit of Continuous Improvement never leaves us alone. (for better or worse, lol)

After months of minor changes and revisions off-line, the 2020 SOP templates have been released. Please note: These are IMPROVEMENTS, not compliance or safety-critical changes. As such, there is no need to go back and change your existing SOPs. We would, however, suggest you use these new formats as you implement new SOPs. Of course, it’s possible, you may want to take advantage of some of the features of these new SOP templates, and you’re welcome to convert to them if you have the time.

Changes to ALL SOP Templates:

Why did we make those format changes?

Additional changes were made to some other SOP templates:

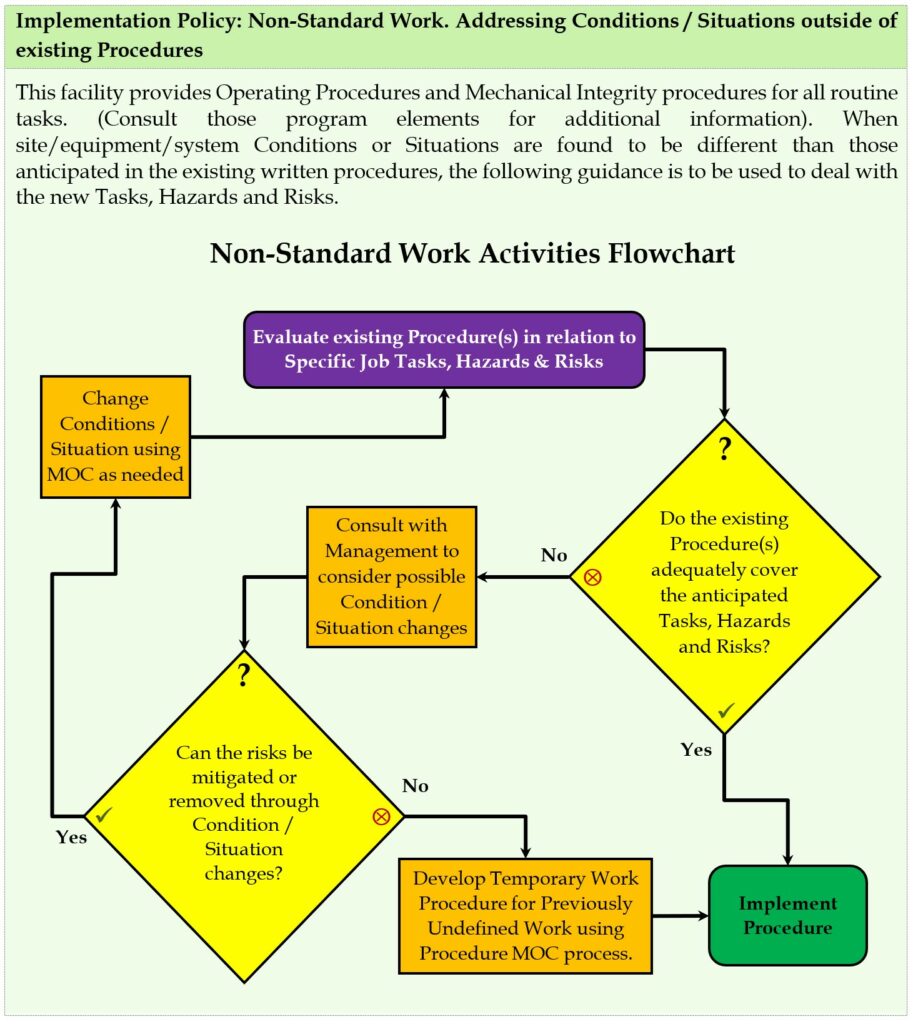

Occasionally we come across an issue we’ve customarily addressed, but never documented. Put another way: We realize we have a policy – even if an informal one – on how to deal with certain situations, but we’ve never turned that policy into a formal, written one.

It’s incredibly common to have these informal policies in smaller departments, or when a task is rare. You can usually identify them after-the-fact when you are told “That’s just the way we do things here. Everybody knows that.”

When we find these items in our Covered Processes, we should endeavor to document them. Today I’d like to talk about a big one: What do we do when the existing written procedures don’t match with the conditions or situations we are facing in our work. What written guidance are you providing to your Process Operators and Technicians on how to deal with this situation?

Every functioning Operations / Maintenance department has a policy – even if an informal, undocumented one – on how they deal with this issue.

For years I’ve relied on the text in the SOP Written Plan concerning Temporary Operations:

The ammonia system is not operated in any temporary modes without a written SOP. If a component requires maintenance or replacement, that portion of the system is isolated and removed from service through a written SOP. Other Temporary Operations are handled through the MOC element which will ensure supervisory oversight. Temporary Operation SOPs are often via a written modification of an existing SOP in the form of an addendum.

This worked well, but it was a little bit obscure and (understandably) only thought to apply to SOPs themselves. That needed to change. What we’ve done to our system today, is formalized and documented guidance on how to deal with these non-standard / non-routine situations.

A new policy was placed in the RMP Management System Written Plan…

To ensure integration of this policy, the following text was added to the Operating Procedures (Implementation Policy: Using an SOP – Performing a Procedure, and Implementation Policy: Operating Phases, Temporary Operations) and Mechanical Integrity (Implementation Policy: Mechanical Integrity Procedures or MIPs) element Written Plans: “The Implementation Policy: Non-Standard Work. Addressing Conditions / Situations outside of existing Procedures found in the RMP Written Plan should be used when site/equipment/system Conditions or Situations are found to be different than those anticipated in the exiting written procedures.”

Are you handling non-standard / non-routine work well in your Process Safety program? If you are, and have a better idea, we’re always open to improvements. If you aren’t handling it well, perhaps you can implement the example above?

For Inside-Baseball type people: This chart was inspired by the API RECOMMENDED PRACTICE 2201 Safe Hot Tapping Practices in the Petroleum and Petrochemical Industries, Chapter 4, Section 4.3.1, Figure 3—Example Decision Process for Authorizing Hot Tapping. Other than genericizing that flowchart to cover all types of work, I also made two large changes: