Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

Chill - We Got This!

Let us help you make sense of PSM / RMP!

We’ll be having an open-enrollment PSM class in Burleson, Texas July 8th-11th 2025.

You can get more information on the class with this link.

We hope to see you there!

Merry Christmas to our Ammonia Refrigeration Process Safety community!

Well, this year has been interesting, eh? The hits keep coming it seems, and it was no different to those of us in the Process Safety field. Behind the scenes, we’ve been working on a fairly major set of improvements to the PSM system. Originally scheduled for August, we’ve finally managed to push it across the finish line just in time for the Holidays!

Significant improvements were made to the core of the system (The SOPs and ITPMRs) through an unprecedented amount of end-user feedback. Remember, this system relies on the feedback of operators, technicians, service personnel, and Process Safety professionals to improve.

All updated documents have the 122520 date-code, but here’s a run-down:

To implement:

From a legalistic perspective, we’ll first turn to the law. In this case, the EPA’s RMP rule…

68.15(a) The owner or operator of a stationary source with processes subject to Program 2 or Program 3 shall develop a management system to oversee the implementation of the risk management program elements.

68.15(b) The owner or operator shall assign a qualified person or position that has the overall responsibility for the development, implementation, and integration of the risk management program elements.

68.15(c) When responsibility for implementing individual requirements of this part is assigned to persons other than the person identified under paragraph (b) of this section, the names or positions of these people shall be documented and the lines of authority defined through an organization chart or similar document.

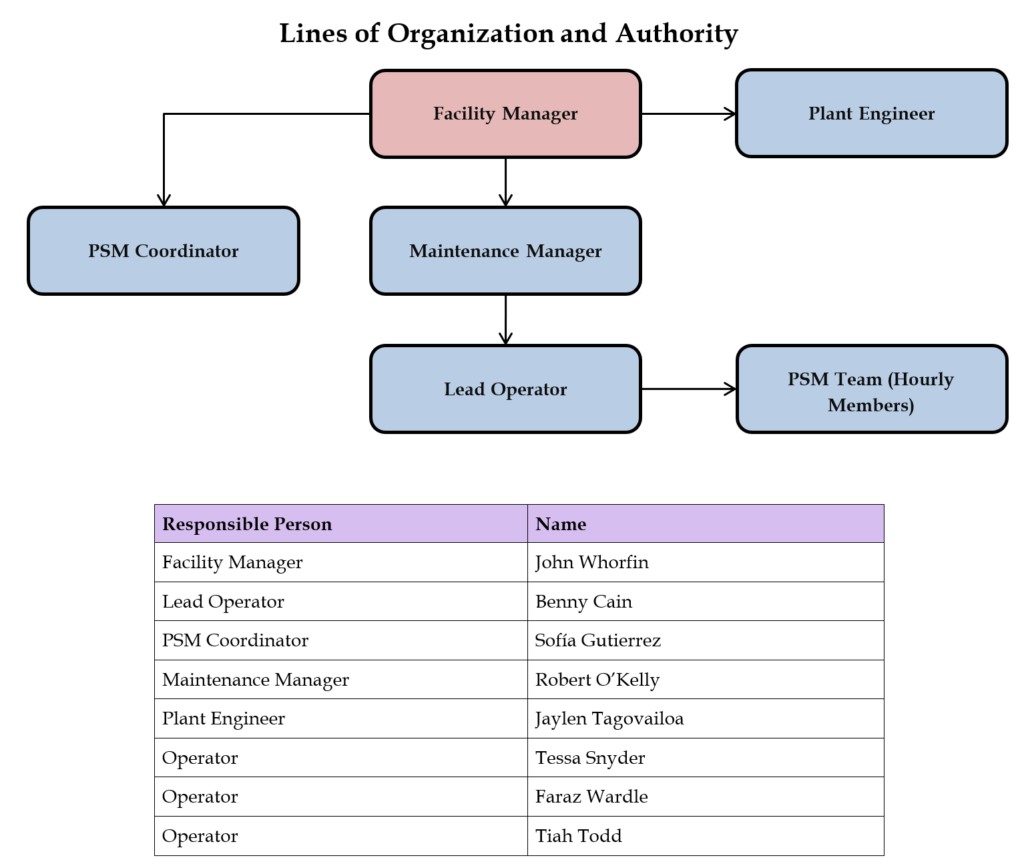

The short, legalistic answer is that the owner/operator is responsible. They must pick a qualified person who has overall responsibility for the program.

If the owner then chooses to break up the various requirements of the program to people other than that qualified person, they have to document all those people. In my programs, I call these people a “Responsible Person.”

Ok, but how does this actually work. Let’s imagine a small facility that is required to have a PSM/RMP program. They pick their Safety Manager, Sofía as their Process Safety coordinator, so she is now the person responsible under §68.15(b).

But, Sofía, while very knowledgeable in Safety and Environmental issues, is not as familiar with refrigeration or engineering. It’s unlikely she’ll be in the best position to manage most of the program elements on a day-to-day basis. To address this issue, the facility decides to assign certain skilled people the responsibility for various program elements. They assign the Operating Procedure, Operator Training and Maintenance elements to Robert, their Maintenance Manager. They also decide to assign the Process Safety Information, Management of Change and Pre-Startup Safety Review elements to Jaylen, their Plant Engineer. Because he usually manages them anyway, they assign Benny, the Lead Operator, the Contractor element. Of course, all these people are going to rely on the knowledge and experience of each other, the Facility Manager John, and the other operators, Tessa, Faraz, and Tiah.

This might be getting a little confusing at this point, which is why §68.15(c) wants us to document these assignments. For example:

| Program Element | Responsible Person |

| Overall PSM / RMP Management System | PSM Coordinator |

| Risk Management Plan (RMP) | PSM Coordinator |

| Process Safety Information | Plant Engineer |

| Employee Participation | PSM Coordinator |

| Process Hazard Analysis | PSM Coordinator |

| Operating Procedures | Maintenance Manager |

| Operator Training | Maintenance Manager |

| Contractor Qualification and Safety | Lead Operator |

| Pre-Startup Safety Review | Plant Engineer |

| Hot Work Permit | PSM Coordinator |

| Incident Investigation | PSM Coordinator |

| Mechanical Integrity | Maintenance Manager |

| Management of Change (MOC) | Plant Engineer |

| Emergency Response Plan | PSM Coordinator |

| Compliance Audits | PSM Coordinator |

| Trade Secrets | PSM Coordinator |

How a facility arranges the responsibilities is entirely up to them as long as they can make the case that the person assigned as a “Responsible Person” is qualified to handle the work being assigned to them.

On a practical level, your Management System should also:

Please note, that just because someone is responsible for an element, doesn’t necessarily mean they are actually doing the work. They are just responsible for ensuring the work is done. A good example outside of PSM is the facility manager of a chicken plant. That facility manager is responsible for ensuring that food safety regulations are met so the chicken is cooled in an appropriate time-frame. It is extremely unlikely that the plant manager actually handles the chicken, the cooling equipment, etc. They simply provide the resources and oversight to ensure the work is done properly.

A good PSM example might be Operating Procedures. In our case, we’ve assigned them to the Maintenance Manager. It is likely that the actual initial creation and review of the operating procedures is done entirely by the operators. Based on the results of that review, the Responsible Person would ensure that appropriate revisions are made and then certify the procedures.

Feel free to contact us If you want templates of a PSM/RMP management system.

It’s been coming for a while now and yesterday it became official:

Introducing: ANSI/IIAR 7-2019 – Developing Operating Procedures for Closed-Circuit Ammonia Refrigeration Systems

In 2013, the first issue of IIAR 7 replaced the operations information contained in IIAR Bulletin No. 110, Guidelines for Start-Up, Inspection, and Maintenance of Ammonia Mechanical Refrigerating Systems.

This standard was first approved as an American National Standard by the American National Standards Institute (ANSI) in August 2013. ANSI requires reaffirmation or revision for periodic maintenance requirements of existing standards every five years. Work began on periodic maintenance of this standard in February 2017 and was completed in April 2019.

This standard defines the minimum requirements for developing operating procedures for closed-circuit ammonia refrigeration systems. Informative Appendix A was added to provide explanatory information related to provisions in the standard.

A little over two years ago, the SOP templates were updated to include all the requirements of IIAR 7 2013. That was a pretty large undertaking, but if you already made those changes, it looks like you are in good shape! I’ve reviewed the new IIAR 7 and it turns out we only need to make one substantive change to programs using the current templates.

What’s the requirement / change?

The 2013 version required a visual inspection of hoses when they were used. This was a pretty minor requirement. The newer version requires that procedures include “Steps to inspect hoses and fittings visually to make sure they are suitable for ammonia refrigeration service” whenever you Transfer (such as in pump-down) or Charge ammonia. To address this issue, I’ve modified the ROSOP-LEO and Permit form to include an explicit check and a reference to the “ITPMR-AHT-365 – Ammonia Transfer Hose Annual ITPM Record” we recently added due to IIAR 6.

So, if you’ve already updated your system for IIAR 6 compliance, then all you need to do is update your LEO procedure and Permit. If you haven’t updated your system for IIAR 6 compliance, then you need to integrate the new ITPMR as well as make plans to address the entirety of IIAR 6.

Note: Overall the 2019 IIAR 7 is much simpler than the 2013 version. It’s moved a lot of stuff to informative appendices which removes most of my complaints about it. Unfortunately they renumbered* just about every single requirement in the standard. This meant I had to completely renumber / rewrite my standalone SOP audit template. The good news is that the IIAR7-2019 version of that audit was reduced from 110 pages to 87. Of those remaining 87 pages of questions, 60 pages are due to IIAR 7.

* This was not an attempt to drive me closer to insanity, but an attempt to harmonize numbering systems between all the IIAR standards. I know this because I actually asked the IIAR about this. Thankfully, Tony Lundell has a good sense of humor.

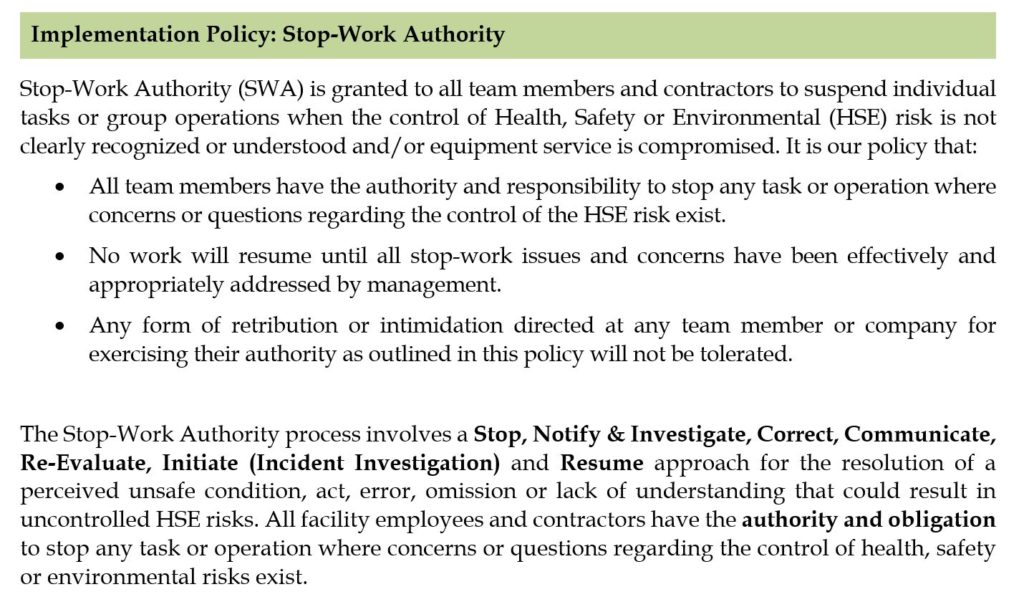

For several years we’ve noticed that many facilities has an unwritten / informal policy regarding SWA or “Stop Work Authority.” What is SWA? Simply put, SWA is a formal declaration that employees have the right (and obligation) to stop unsafe work when they become aware of it.

While the safety culture at most facilities implies that employees have Stop Work Authority, it is rare to see a written plan that addresses it. Since we believe that SWA is a vital part of a functioning safety culture, we have written it directly into the Employee Participation element’s Written plan.

If you use our PSM/RMP templates, you will find the updated documents on the shared drive. Below is an excerpt of the policy section:

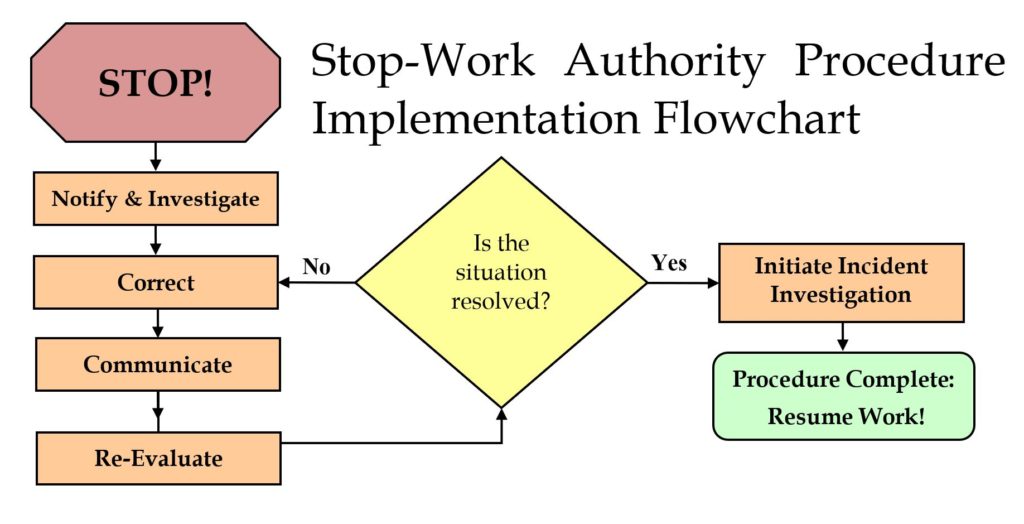

The Written Plan includes an explanation of each step in the process. We’ve also included a poster to be used in the workplace:

In mid-february we changed every reference to Guideline in the example templates to Written Plan. This change was made to the Google Drive and logged on 2/3/17.

Although I have used the term guideline for a very long time, it was really just out of habit – it’s not an accurate reflection of the intent of those documents.

Well, it all started back in the Employee Participation element which requires you to have a document that explains how you intend to comply with certain requirements.

1910.119(c)(1) – Employers shall develop a written plan of action regarding the implementation of the employee participation required by this paragraph.

Over time we realized that these written plans of action were very useful and wrote them for every single PSM/RMP element. For whatever reason, the very first program I ever worked on called this the “Guideline for Employee Participation” and I just stuck with that wording for well over a decade.

Well, let’s look at definitions:

A dictionary definition of guideline is:

“General rule, or piece of advice”

The word plan defined in that same dictionary:

“a detailed proposal for doing or achieving something;”

“an intention or decision about what one is going to do.”

The word plan is really what we are going for: A decision about what the facility is going to do. The intent of these documents, whether they are called Written Plan or Guidelines, was always to document the detailed plan that the facility intended to follow in achieving compliance.

Actually, yes. Over the years we had to explain the above to several different inspectors: our Guidelines were actually our written plans. Frankly, it just got annoying explaining the same concept over and over again – especially when they had a point: Rightly understood the documents really are the written plan and general guidance usually used the guidelines terminology such as the IIAR Compliance Guidelines and the CCPS Guidelines for Safe Process Operations and Maintenance.

Well, no you never really have to update your program to reflect our changes. That said, Should you? Yes, you should make the change whenever you update your program to the latest templates.

Many of the readers of this website have PSM/RMP programs written using our Open-Source PSM templates. The members of our community have read-only access to the Google Drive templates directory where the newest revisions and updates to those documents are housed. While we’ve kept a “Change Log” in the root directory of that shared drive for a long time, we’ve recently decided to make a blog post about every template change to raise awareness of these changes and assist those of you who want to continue updating your program. What follows is our first blog post along those lines:

PDF “Form” versions of commonly used MI & PSSR Forms

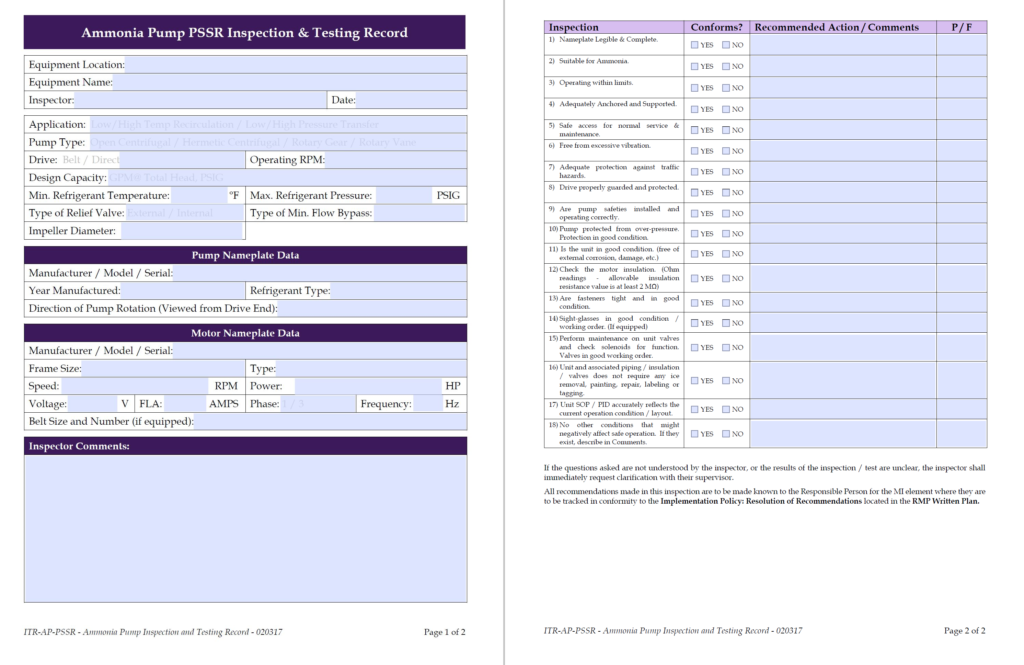

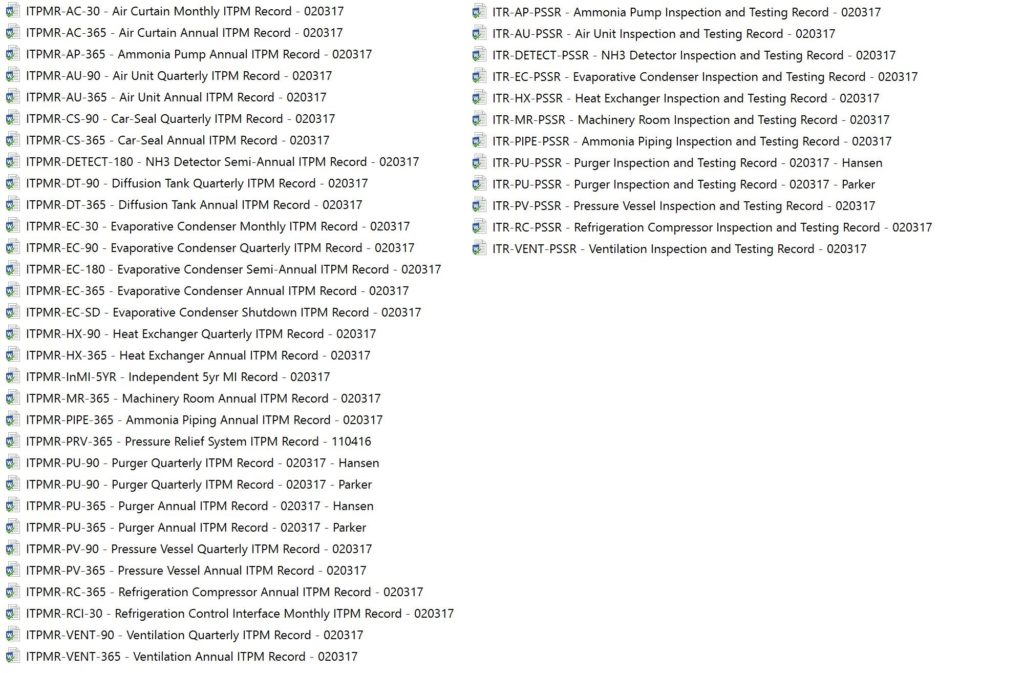

Back in July of 2016 we first introduced documents to our PSM Template system called ITR-PSSR forms. These “Inspection Test Reports for Pre-Startup Safety Reviews” provided a standard format for new equipment documentation and safety checklists that replaced the B109 form that some people use. Unique forms were provided for common subsystems and equipment, such as:

In September of 2016, we provided PDF versions of these as “PDF Forms” that were usable for data entry. At some point, those files were apparently removed or lost. I recreated those PDF forms today for all the ITR-PSSR Forms.

I also converted each of the ITMPR forms. These “Inspection Test & Preventative Maintenance Reports” form the basis of our Mechanical Integrity program documentation. Both the ITPMR and ITR-PSSR forms are now on the Google Drive in their respective PSM element folder. The revision dates of the PDF reflect the revision date of the original Word document.

Can I use these in my program?

If you use our templates, or we wrote the program for you in the last two years using these templates, then the answer is Yes, but how easily depends on the age of your program.

If your program is newer than September 2016: Those of you who use our PSM/RMP templates to create their own programs – or those of you who have a program we created post September 2016, can drop these updated forms directly into your program.

If your program is older than September 2016: If your program was created before September of 2016, the ITR-PSSR forms can be added to your program as alternate PSSR documentation. Your MI documentation were called ITR forms at the time – not ITPMR. To replace the ITR forms with the updated ITPMR forms you can do one of two things:

OR

Regardless of the age of your program, make sure you conduct a brief training with your operators on these new forms before your implement them.

Here’s a list of the updated files that now have PDFs available on the Google Drive:

The SOP reference element guideline and RESOP/ROSOP reference templates have been updated for 2017. The changes are basically broken into two groups: Continuous Improvement and IIAR 7.

Continuous Improvement: As always, there are a lot of little change suggestions that have been built up over time that were expressed in different templates in slightly different ways. Here are some of the change highlights in this section:

IIAR 7: I have long bypassed IIAR 7 “Developing Operating Procedures for Closed-Circuit Ammonia Mechanical Refrigerating Systems,” preferring to use the CCPS “Guidelines for Writing Effective Operating and Maintenance Procedures.” While my reference templates still use the CCPS as their basis, I felt it necessary to perform a Gap-Analysis between the templates I’ve been using (and continuously improving) for over a decade and the requirements in IIAR 7-2013. This is especially important because the International Machine Code (IMC) has been updated to point to IIAR 2-2014 (Safe Design of Closed-Circuit Ammonia Refrigeration Systems) which references IIAR 7-2013. While I am still not calling IIAR7 RAGAGEP in my PSM programs, I wanted to ensure that the PSM program SOP(s) were compliant with it. While there were no significant changes necessary to make the templates more compliant with IIAR 7, some changes were necessary. Here’s what changes were required for IIAR 7 compliance:

For those of you who use these reference templates, they are available in the Google Share in a directory called “IIAR 7 Mods.” After a few months of trials and minor revisions, these templates will replace the existing templates in the main directory. The old templates will be rendered obsolete and moved to the 0bsolete directory.

If you have existing SOPs using the 2016 (or earlier) versions of the template, you will want to compare the new templates with your existing implementation. Please note: These new templates will be the basis for ALL future template modifications / updates.

Below is a list of ALL the changes made to the SOP template section.

Yes, there are a LOT of changes! If you want any assistance or clarification on any of these changes, feel free to contact me.