Imagine we’ve decided to replace the existing fans of an air unit (probably a blast cell) with composite blades. Should you consider that a Replacement in Kind?

Before we go into the change, you might be asking why people would change from a metal fan to a composite. The answer is usually three-fold:

- Composites allow for some really elaborate / efficient shapes that are difficult to pull off with traditional metal blades. This means that the fan blades can be designed for low noise or to maximize throughput / throw. It’s not uncommon to see a composite blade manufacturer claim a 5% energy savings by using these types of fans.

- Corrosion Resistance. The commonly used FRP (Fiber reinforced polymer) blades are more resistant to common cleaning chemicals and water than traditional metal fans.

- Composite fans usually provide a far better weight/strength ratio than even cast aluminum. This means higher efficiency, lower motor wear, etc.

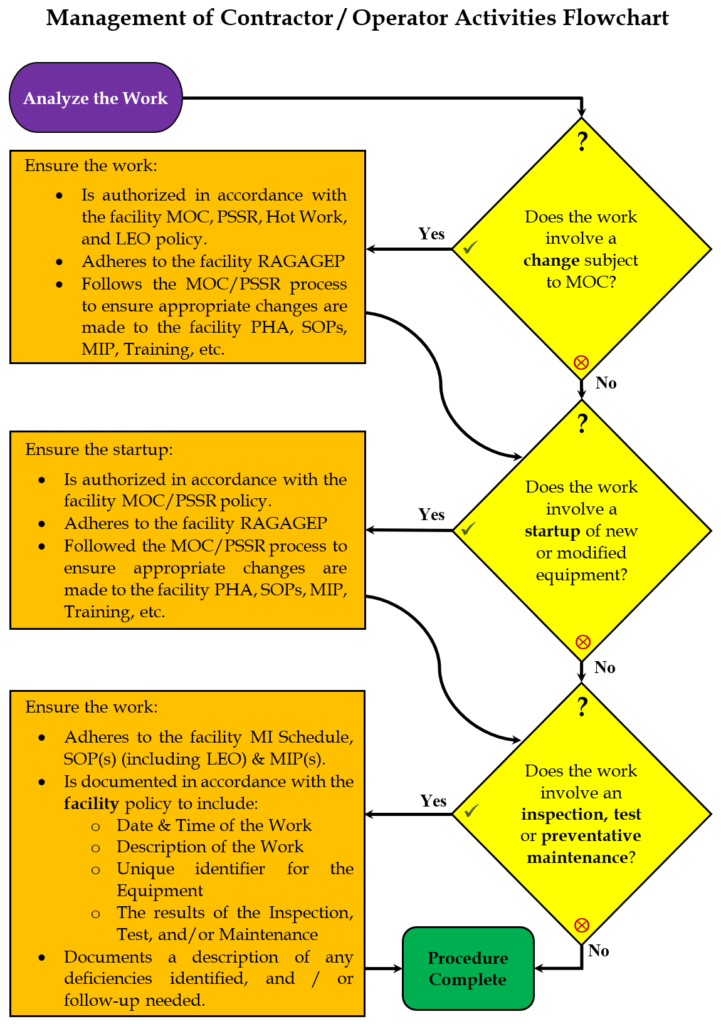

Should you consider the replacement of traditional metal fans (in an air unit for example) as a Replacement in Kind? My thinking on this is the same as the answer to every other “Is it a Replacement in Kind” question: It’s a change that falls under the MOC procedure(s) until you prove that it isn’t.

To meet the lowest possible compliance threshold of OSHA and the EPA we have to know if it “satisfies the design specification.” In this case, that pretty much comes down to asking if it has the same (or better) performance characteristics as the fan it’s replacing.

Assuming you do those checks, and you find the new fan can operate at the same temperatures, static pressure, speed, etc. as the old fan, OSHA and the EPA would allow us to qualify this as a Replacement in Kind. As always, I would suggest you document that work so you can prove you’ve correctly qualified the change as a Replacement in Kind. That’s the minimal compliance answer. The process safety answer is different and it’s the answer you should care about!

For the process safety answer we also ask a few more questions. For example:

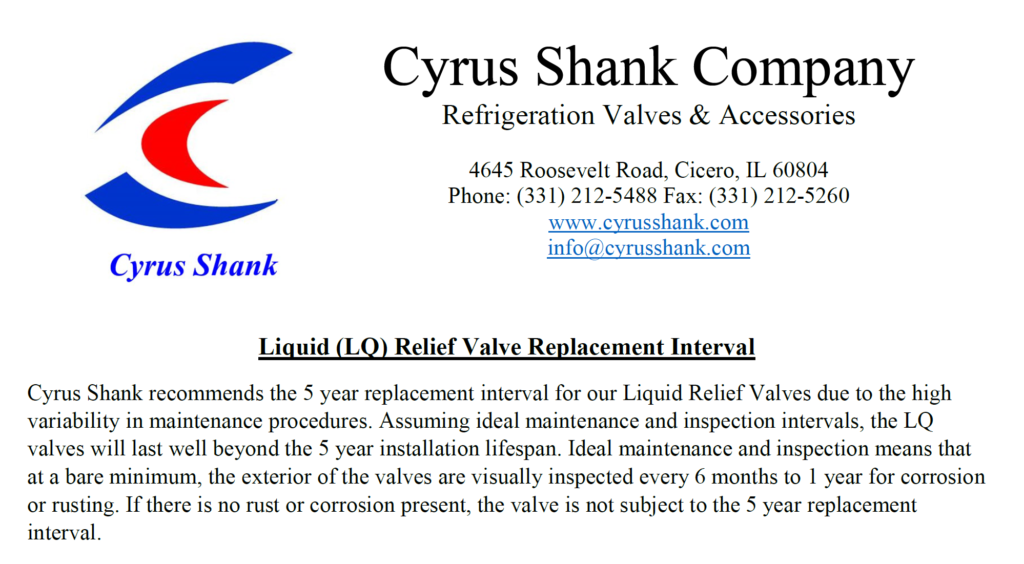

- Does the fan have the same MI requirements?

- Does the fan have the same failure modes?

- Are our PHA answers concerning fans (evaporators, condensers, etc.) still the same based on these new fans?

I would like to focus on the PHA question because the others are part of our PHA answer. If you are using the IIAR’s What-If checklist (or something like it) you have a question that looks like this:

EV1.22 What If…a fan fails catastrophically? (air unit cooler only)

It’s likely you answered that for metal fans by saying there were appropriate safeguards to control this hazard such as your MI program, daily walk-through’s, 5yr independent inspections, etc. It’s also likely that if you had those safeguards in place you made “no recommendation” on that question.

Now, let me ask: What if the new fans have different failure modes / MI requirements? Wouldn’t that change your analysis?

Recently I’ve been getting reports of fan failures in the field. While not unheard of with traditional metal fans, these reports lately seem to all be about composite fan blades.

What we seem to be seeing in these composite fan failures is that they appear to be caused by:

- Turbulent uneven air flow through the coil (usually caused by debris on the coil but could also be caused by partially blocking the airflow out of a coil)

- The turbulent air flow causes the fan to oscillate, sometimes at a resonant frequency

- Over time this resonant frequency causes small stress cracks to start on the fan blade at the hub

- If the condition lasts long enough, the crack propagates, and the fan catastrophically fails

Now, that’s not a failure mode / sequence of events we are used to seeing on traditional metal fan blades. Does that mean we shouldn’t use composite blades? No, of course not – it means Identifying new hazards like this requires us to institute new / altered controls. Some good examples of appropriate changes:

- LOWER our acceptable threshold for debris on air unit intakes. This could mean more walk-through’s or just more debris removal. We’re not talking about dust buildup here, we’re talking about the removal of large debris: cardboard chunks, labels, etc. The things that are likely to cause turbulent and uneven flow through the unit.

- LOWER our acceptable threshold for product blocking airflow out of a coil.

- Specifically look for signs of cracks during annual / 5yr MI inspections.

Making changes to our program like this show us that the change from a traditional fan blades to composite fan blades should not be treated as a Replacement in Kind. It is, however, a fairly simple Management of Change. I want to re-emphasize here, had we chosen to view this change as a Replacement in Kind, we would have missed these opportunities to identify and control these new hazards introduced by the change.